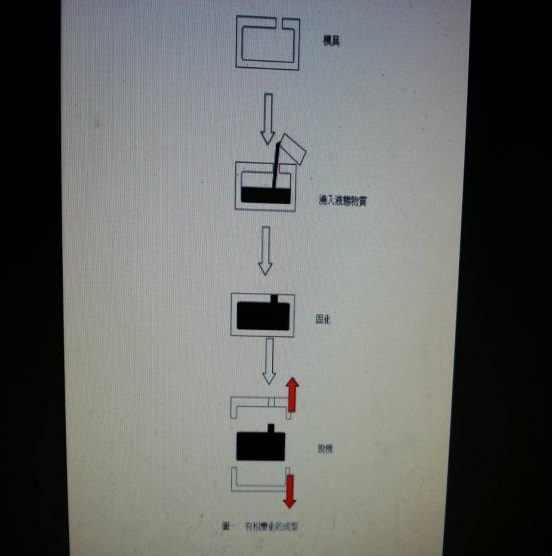

First, what is the mold:

First mold according to the shape of the processed into the mold cavity (and sometimes to use another model to form the cavity)

Then pour the liquid material into the mold cavity, wait until after pouring to form a solid, and then remove the mold to mold the content is completed.

Second, the introduction of mold technology:

There are many applications for forming by this method. The earliest mankind used this principle to cast bronze and bronze age.

Many of the finest bronze wares in ancient China were so elaborate that the shape of their mold cavities was very meticulous.

Making the casting of the finished pattern detail (of course, when casting copper composition and temperature control is also very important).

After the past few thousand years of development principles are the same, and change is the mold material, the material being molded,

According to this basic principle a variety of manufacturing methods have been developed.

Introduction three kinds of mold: gypsum mold, turning sand mold , CNC aluminum alloy die.

1 gypsum (wood) mold: Mold materials are mostly plaster, wood, mainly for art sculpture, with the advantages of customization, uniqueness.

On the contrary, the disadvantage is the mold is not durable, not suitable for long-term production.

2 sand mold

Relying on sand and mold and other raw materials into the metal into a product, called sand casting.

The first metropolis of the mold wood first mold for the mold, the mold made of metal mold.

3 CNC aluminum die

Belonging to industrial molds, in the mold making process, the biggest focus is accurate size, mold on time test mode.

Will use CAD drawing software mapping, and the use of CNC high-precision mold making machine.